In addition to our standard product range, we also offer you different special solutions for our gas springs.

The SUSPA TouchLift is a gas spring that locks itself in the retracted position. In this way, for example, covers can be kept in the lowered position. Slight pressure on the cover releases the lock and the gas spring extends. The lock works according to the so-called ballpoint pen principle:

| Stroke | Tolerance ±2 mm | Extension length ±2 mm | Part number |

|---|---|---|---|

| 150 | 248 | 398 | 01615067 |

| 200 | 301 | 501 | 01615068 |

| 250 | 363 | 613 | 01615069 |

| 300 | 141 | 714 | 01615070 |

| 350 | 468 | 818 | 01615071 |

| 400 | 520 | 920 | 01615072 |

| 450 | 558 | 1,008 | 01615073 |

SUSPA offers you the ideal solution for the furniture sector for the opening function of your cabinet door.

The standard gas spring as well as the soft-stop gas spring are both extension-damped. After an opening angle of about 10°, the cabinet flap opens automatically with both types up to an end position of about 90°.

The positioning gas spring is the right solution if a furniture door or flap is not to automatically open all the way to the uppermost position. The gas spring supports the force, but remains securely in the respective position desired by the user. An interim stop is also possible in any position.

We offer you our furniture gas springs for the following flap materials.

In automotive applications, gas springs aid the opening function of tailgates, trunk lids and hoods. They control the opening behavior and can be used wherever a functionally reliable and convenient operation is expected with a low energy expenditure. Gas springs are the ideal opening aids due to the flexible adjustment of forces with constant dimensions and due to the flat characteristic curves.

Contact us to find the right solution for your application.

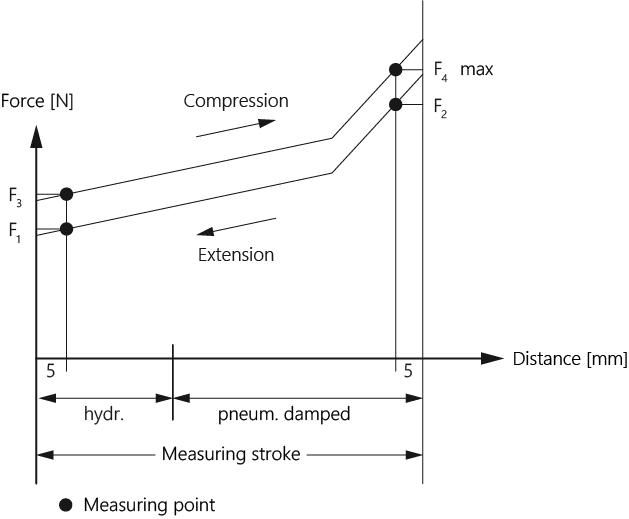

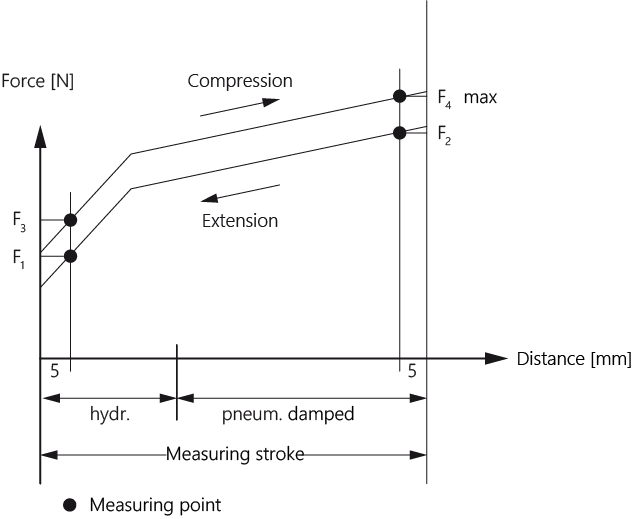

The spring characteristic (force progression) changes by means of a gas spring with an integrated mechanical spring.

A force diagram with a progressive characteristic curve (progressive course) is created due to a mechanical spring in the pipe between the piston and bottom of the pipe.

A force diagram with a degressive characteristic curve (degressive course) is created due to a mechanical spring.

The standard gas spring as well as the soft-stop gas spring are both extension-damped With both gas spring types, when lightly lifted the flap opens automatically after an opening angle of about 10° until an end position of about 90°. To minimize vibrations, the speed is controlled throughout the entire opening range by means of a special groove-controlled damping (extension-damping), which makes uniform opening possible. It is possible to optimize the pneumatic spring to the respective installation situation by pre-setting the filling pressure during production.

The gas spring with lubrication reservoir is based on the Space-Mat principle. This principle means that a plastic foam that is around the piston rod absorbs lubricants via capillary effects in the cavities and dispenses them again later when lubrication is needed. This significantly improves the service duration of the pneumatic spring, especially when used in technically demanding environments (dirt and dust).

If the gas spring is used in a particularly dirty or dusty environment, it may be necessary to protect the seal by using protective caps made of rubber or plastic. The protective cap is intended to ensure that no dirt and dust particles in the environment penetrate into the pneumatic spring seal when actuating the flap. Using the protective cap therefore also has a positive effect on the service life of the gas spring in these installation situations.

In an extremely dirty environment, the protection that is guaranteed by the protective cap may not be sufficient. In these extreme environmental conditions, it is advisable to use a Space-Mat gas spring (gas spring with lubrication reservoir) from SUSPA.

The positioning gas spring is the right solution if a flap is not to automatically open all the way to the uppermost position. The gas spring supports the force, but remains securely in the respective position desired by the user. An interim stop is also possible in any position. The gas spring can be optimized for the respective application due to the different fill pressure.

Easily, quickly and conveniently configure your custom gas spring from various versions and connections with the CAD configurator.