Specific design of gas struts increases service life and safety of moving components.

Every movement under control: individually adapted gas struts

Gas struts facilitate the lifting and lowering of machine flaps, skylights, height-adjustable desks and hospital beds. In order to move precisely to the desired position, they should be adapted to the specific application and installation location. Suspa offers tailor-made solutions with matching special functions for the individual case.

Gas struts are responsible for the opening, closing, tilting, lifting and lowering of flaps, tables, seats and beds. They ensure controlled movements defined to precisely adapted speeds and according to the frequency of the actuation. "Different gas pressures and forces can be realized in the same installation space. Therefore, there is a wide range of applications for gas struts," said Andreas Strobel, Sales Manager at Suspa GmbH. Gas struts are used in our daily lives and in the industrial environment. They offer safety when lifting hatchbacks on our cars and assist in the quiet and easy movement of furniture flaps in kitchen storage systems. This can also adjust the position of your favorite easy chair and bring your desk to an ergonomic working height. Equipped for extreme loads, such as dust, dirt and vibrations, gas struts are also used in the industrial sector in order to open and close protective covers, maintenance hatches and other machine components. Comfort and safety are guaranteed with the controlled movement process.

However, every installation situation requires a custom configuration of the gas struts. With gas strut manufacturer Suspa, the function of the overall application is emphasized. The gas struts are individually adapted to the requirement profile in regard to kinematics and damping characteristics – even if there are special requirements for the gas struts, such as harsh environmental loads, such as dust, dirt and moisture. Suspa offers a variety of time-tested special functions and special equipment for these installation situations.

Gas struts can be controlled precisely

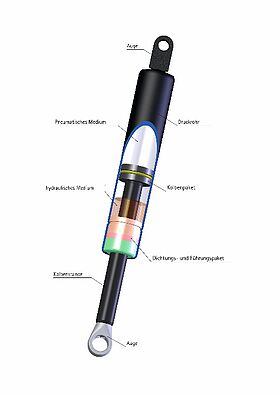

A gas strut or gas pressure spring is a hydro-pneumatic adjusting element that is essentially a closed unit comprising a piston rod, piston and pressure tube and is filled with nitrogen and hydraulic oil for lubrication of the sealing and sliding surfaces. Gas struts can effectively replace mechanical springs, because they are pre-loaded with extremely high fill pressures and do not have to be compressed before they provide high forces. The most important advantage over mechanical springs: the extension speed can be controlled. The gas volume compressed in the pressure tube is closed on all sides and the pressure acts on the entire piston surfaces. Since the contact surface of the piston is smaller on one side (reduced by the cross-section surface of the piston rod), the gas strut extends. "If you had no damping, the piston rod would shoot out like a normal spiral spring. This effect is not desired. Therefore, the piston, which forms two chambers in the pressure tube, is provided with a bypass (a small hole or recess)," explained Andreas Strobel. This makes it possible for the gas to move from one chamber to the other. The speed at which the gas strut extends is defined depending on the size and number of recesses or holes – which makes it possible to control the speed of the struts.

A special version for path-dependent speed regulation is the channel gas strut. The piston is completely closed in this version. The pressure tube is provided with a defined recess (channel) in which the gas can pass by the piston from chamber to chamber. The channel depths can be varied in order to influence the gas flow rate. If the flap of a kitchen cabinet should start to open quickly at first and then only very slowly the final 20 degrees of the opening angle, the gas strut channel should be deeper at the point where the gas strut should extend quickly than towards the end of the stroke, where slower extension is desired. In this manner, the gas strut provides a soft stop; the varied damping over the length of the stroke provides a gentle movement of the flap.

Life-extending measure with SpaceMat protective cap

In order to be able to customize a gas strut for the application, precisely defined specifications are needed. The speed control is only one of these variables. Additional parameters include the available installation space, the necessary stroke, the type of hinge or opening and pivoting angle. The conditions in the installation location also have an essential influence on the design. If environmental influences such as road dust, water, mist or particles from materials processed in machines are unavoidable, special protective measures for the gas struts are necessary.

Suspa has developed the special equipment "SpaceMat" for heavy-duty applications, such as road machinery, combine harvesters and industrial production lines. This lubrication system consists of a protective cap with integrated plastic foam (elastomer) that is drenched in a special fluid (oil). The elastomer surrounds the piston so that the lubricant is absorbed into the micro-scratches in the surface of the piston rod by means of a capillary action and a purposeful lubricating effect is provided. The cap is affixed on the gas strut tube. With each movement of the piston rod, dust and dirt are wiped off and the piston rod and seal are wetted with the oil. SpaceMat also provides protection from corrosion on the casing and thereby extends the service life of the gas strut. An additional positive effect: the gas strut, which must normally be installed with the piston rod facing downward, can also be installed in the application in the opposite direction. The seal, which would run dry in installation situations with piston rods facing upwards, also remains wet with oil in this position, thanks to this lubrication system.

Equipped for special cases

Suspa offers a special piston design with the HydroLine. Unlike conventional gas struts, the piston is closed the starting position. An additional valve in the piston assembly enables the exchange of gas, and thus movement, after a defined load threshold. The valve system is released with the application of force from outside, e.g. with the movement of a flap by hand. Then the gas can flow through an opening between the chambers. It works like this: if higher weights would unexpectedly force a gas spring to retract, the HydroLine system acts an additional block. This is advantageous for cases such as heavy snow loads on skylights.

The valve system also makes it possible for the user to hold the object in an arbitrary intermediate position; it is also possible to balance out the weight for defined movement controlled by hand. In addition to window applications, this special solution is advantageous in mechanical engineering, if different forces act on flaps within a machine or are operated by employees of different sizes, but should only be equipped with one gas strut model.

Piston rods: all production steps under one roof

"The piston rod is essentially the core of every gas strut," said the sales manager. In order to ensure a long service life of the gas strut, the tribological system – piston rod, seal and oil – must be harmonized. In the process, the piston rod is a compromise of the ideal surface roughness, which stores the oil, but must not be too rough in order to avoid wear on the seal. The piston rods made of simple steels, stainless steels or aluminum receive high surface quality in finely tuned production steps. "Turning, hardening, grinding, surface-coating and polishing of piston rods are all carried out by Suspa in-house. Shortened delivery times, reduction of costs and optimal quality can only be ensured when everything comes from a single source," said Andreas Strobel. The grinding machines, lathes and surface refining systems are all located on site. In addition to chrome-plating for low friction and durability of the piston rods, the Altdorf-based company offers liquid nitriding for very high requirements for anti-corrosion protection. The result is black piston rods with extremely hard and smooth surfaces that are not susceptible to corrosion from harmful influences. The roughness values of the piston rods are in the micrometer range. "However, the purpose is not to achieve a value of zero. It is more important to achieve the exact value required by the application and maintain it in series production so that surfaces are neither too smooth nor too rough," said Strobel.

In addition to traditional piston rods, the gas strut manufacturer offers versions offering the possibility of complex geometries, such as transverse holes, milling, various diameters and axial deep-hole drilling. "We have so much experience in the design and production of piston rods that many of our customers, including manufacturers of shocks and struts for vehicles and hydraulic cylinders, purchase their piston rods exclusively from us," added Strobel.

9,860 characters