Vibration-free hospital bed side elements with hydraulic damper HD 15

The hydraulic damper HD15 from gas strut manufacturer Suspa is a special solution that is used predominantly for the operation of hospital bed side elements. Special requirements for damping systems arise in this environment. Reliable, comfortable and vibration-free adjustment of the side elements are the primary tasks of the HD 15.

The application-specific requirements of a damping system used for adjustment of the side elements of hospital beds are very special. In addition to simple operation, the damping system must be capable of installation in a very small space and be characterized by a moderate assembly effort and expense in the price-sensitive health sector. In the process, the damping must first guarantee efficient lowering of the side elements in order to ensure quick, unimpeded access of the care personnel to the patient and, secondly, suppress shock of the side element in the "open" limit position with controlled damping and thus protect the patient from vibrations.

Four side elements, four HD 15 dampers

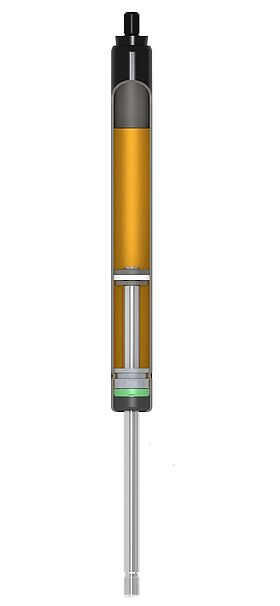

Taking these basic requirements into account, Suspa developed the HD15 hydraulic damping system. The product is part of the Softline series. It consists of a pressure tube, a piston rod manufactured in an in-house piston rod production line, a special piston rod, and oil as a damping medium. Because the HD 15 must be assembled with a downward-facing piston rod, the system is normally in the retracted state when the side element is up. The piston rod is then completely retracted in the tube. If the HD 15 is in the extended state, the side element assumes a completely lowered position. Because most hospital beds are equipped with a total of four side elements, four HD 15 damping systems suffice for the operation of the side elements in order to fully equip each element.

Individual damping force - application-specific damping profile

According to the hydraulic functional principle of the HD 15, the piston meets the oil column in the tube when lowering or extending. Depending on how quickly or slowly the oil flows through the holes in the piston with actuation of the piston rod, a corresponding damping force is generated, which absorbs the lowering energy of the side element. The damping force can be customized with the construction and design so that it is possible to factor in customer wishes, such as a desired speed, maximum time or special damping profile. When lowering, the system automatically moves to the limit position after the manual release; manual force must be applied when raising in order to move the system to the "top" limit position and it must be locked in place there manually.

High damping force prevents rebound effect

The HD 15 ensures a guaranteed maximum damping force of 500 Newtons (N). It has a progressive damping characteristic curve. In other words, in order to initiate the smoothest possible lowering

acceleration of the side elements after manual release, the HD15 initially generates an idle stroke in which the rotation of the side element moved downwards without any damping resistance. At the end of the lifting path, the HD 15 provides the maximum damping force in order to eliminate vibrations and any rebound effects, which can occur, for instance, in spiral spring systems. The setpoints for the duration of the lowering are within a time range of two to five seconds.

The ergonomic effect for the care personnel is an additional important factor. The comfortable unlocking mechanism and the damping of the HD 15 relieve the operator's muscular-skeletal system, because the rotational movement does not have to be monitored in order to ensure that vibrations are prevented. If the side element is not locked, the care personnel can proceed with their medicinal tasks immediately, because the HD 15 damping system ensures vibration-free lowering automatically. Control of the lowering process with manual application of force and an unpleasant, bent-over posture is not necessary.

Construction concept with optimized kinematics

Hospital beds must fulfill certain size requirements. This condition also applies to the HD 15 damping system, which is used in the side elements. If a side element moves from top to bottom, the movement draws an imaginary three-dimensional parallelogram and consequently completes an outward pivoting movement in order to assume a parallel end position back towards the bed. However, because the tube with a diameter of only 15 mm is a mere 65 mm long (without boss) when retracted (top side element position) and the overall length of the complete damping system is 140 mm when the piston rod is extended, this movement assumes the shape of a very narrow parallelogram that is executed closely to the bed. In the fully lowered limit position, the upper edge of the side element is below the top of the mattress. The distance between the mattress and side element is very short in both limit positions. The kinematically beneficial characteristics of this design concept provide a number of advantages. For example, the side elements can be easily operated in confined spaces, which can arise in emergency situations during patient transport within the hospital, e.g. in lifts.

Guaranteed durability

The HD 15 offers outstanding durability. Suspa guarantees tens of thousands of movement cycles for the HD 15 – one movement cycle consists of a complete lowering and lifting rotation. Because an exorbitant actuation frequency is not expected, unlike flap applications in kitchen furniture, this frequency volume is more than sufficient to keep a hospital be with HD 15 damping systems in service for a long time.

The HD 15 can be filled with different hydraulic oil types having different chemical compositions and viscosity in order to achieve a customized, application-specific movement and rotation profile. All hydraulic oils that Suspa used with this solution are food-compatible, chemically safe for people and animals and fulfill the clinical hygiene standards required by hospitals.

Suspa offers alternative Softline damping systems for heavy-duty applications, such as motor bearing or vehicle seat damping. They are qualified by a larger tube diameter, thicker walls and a significantly higher damping forcer for applications with high-frequency movement profiles.

Keystrokes: 7,126