SUSPA® provides you, as a development partner, different products for the automotive industry such as pneumatic springs, dampers, adjustment systems, crash management systems and steering column dampers.

Already since the early 2000s, SUSPA® has developed and produced in series the first active spoiler systems for renowned sports car manufacturers. We have now become the market leader in this field.

In addition to the classic rear spoilers, active front and underbody spoilers are also gaining importance. SUSPA® also develops customer-specific solutions for this purpose.

With the active roof edge spoiler, we offer technical solutions to improve the aerodynamics and thus reduce the cw-value or improve the driving dynamics.

In addition to the usual active adjustment systems, SUSPA® actively develops aerodynamic air guidance systems that help to optimize the overall aerodynamic performance of the vehicle at different points on the automobile.

Developed and produced for customers on a project basis

SUSPA® is also a provider of convertible roof locks and side flap drives.

For a convenient access to tailgates and doors, we offer tailor-made solutions that allow for a fully automatic opening and closing of the tailgate / trunk lid or the vehicle door.

SUSPA® develops, for example, lowering mechanisms that make dangerous outer contours disappear in fractions of a second in the event of a crash with a pedestrian. In the interior area, we are available as a development partner and series supplier for adjustable comfort features.

Due to the steadily rising requirements for the acoustics of adjustment systems, we have built up our own expertise in the design, development and production of high-performance and low-noise motor/gear units.

The steering column damper co-developed and built by SUSPA® is an irreversibly operating damping element. The steel tube-in-tube system is built as a supporting element in the steering column and is above all used in the event of high-speed accidents. If the driver hits his or her upper body on the steering wheel collapsible collar, the inner tube pushes through the outer tube. In the process, the movement of the upper body is braked so that the risk of injury to the driver is greatly decreased.

The special features of the SUSPA® steering damper are a simple graduated force level (e.g. against misuse), an extremely constant crash force across the entire crash path, a constant crash behavior regardless of the installation position (the damper is identical from sports cars to delivery vans) and very high flexural and torsional rigidities, despite the tube-in-tube design.

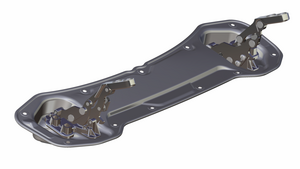

Crash management systems (CMS) are installed behind the hood and rear trim on the front and rear of the vehicle. CMS are used to minimize damage to the vehicle structure and expensive components in the event of accidents at low speeds up to 16 km/h. Modern systems are also designed to reduce the risk of injury in the event of accidents with pedestrians.

The CMS developed by SUSPA® are preferably made of aluminum and, beyond the described requirements, are characterized by the very high level of efficiency (= less required installation space), high proportion of the same parts even with different versions, simple adjustment of the crash forces for different vehicle weights within a series, and the extended possibility of assembling different components (e.g. sensor system).

![]()

In automotive applications, gas springs aid the opening function of tailgates and hoods. They control the opening behavior and can be used wherever a functionally reliable and convenient operation is expected with a low energy expenditure. Gas springs are the ideal opening aids due to the flexible adjustment of forces with constant dimensions and due to the flat characteristic curves.

![]()

The oil damper is a hydraulic motion damper that, for example, controls the opening behavior of a trunk lid driven by a tension spring. The goal is to realize a harmonious opening process and to avoid the trunk lid from overshooting the end of the stroke. A path-dependent damping can be realized by using a bypass groove in the tube.

The "flapstop" stop damper is a hydraulic damper that brakes a flap or door due to its special identifier. In this way, there cannot be damage to the vehicle even in the event of misuse. The gap dimensions can thus be minimized by the flap stop so that the flaps and doors close smoothly. Additional functions, such as the "pop-up," can be integrated.

SUSPA® offers you systems for the optimal seat comfort, which are particularly suitable for professional drivers. You get a perfectly tuned performance for every application case due to the adjustable and non-adjustable hydraulic dampers. We find the right hydraulic damper for every application by selecting the ideal characteristic form (digressive, progressive, linear). For the driver's seats in commercial vehicles, we offer 2-tube hydraulic dampers, among other things, that ensure maximum seat comfort due to their adjustability.